BEST PRICE GUARANTEEOn Many Items

MONEY-BACK-GUARANTEE

Relaxed shopping

EXPERT ADVICE

From athletes for athletes

PAYMENT METHODS

Powermetershop.de - The Power Meter Specialist

We are an online store specialized in power meters. In addition to the online store, we run a bike workshop for road, triathlon and time trial bikes in Berlin. If you need assistance with the assembly of your power meter, we will be happy to help you in our bike workshop.

Power meters have drastically changed — not to say, revolutionised — how cyclists and triathletes train and compete.

As trainers and former professional athletes, we cannot stress enough the positive impact a power meter has on training. Much has changed since SRM brought the first commercial power meter to market in the late 1980s. The first devices were large, heavy, not particularly user-friendly, and above all, extremely expensive.

Nowadays, power meters are lighter, smaller, more accurate, and cheaper. Over the past few years, more and more manufacturers have been bringing products to market, sometimes with innovative ideas and solutions. Today, athletes can choose from a large selection of various systems with specific advantages and disadvantages. It quickly becomes difficult to get your head around... We are an online shop that specialises in power meters: our customer service team knows everything there is to know about power meters, and can answer almost any question on the subject. We would be happy to help you find the right power meter for your requirements and for your bike.

What is a power meter?

A power meter is a device on a bicycle that measures the force/power put down by the athlete.

Most power meters use "strain gauges" to measure the force exerted through the pedals. They are slightly deformed during pedalling (to a microscopic extent). This enables the force to be measured. However, power is not force: rather, it is the quotient of work performed (force x distance), and the time required for this. Distance in this case is represented by crank turns. As a result, power meters measure pedal rate as well as power.

In this sense, a power meter calculates power, rather than measuring it directly. Power and other parameters (e.g. pedal rate) are then transmitted by radio (previously by cable) from the power meter to an appropriate display device, generally a bike computer.

Who needs a power meter?

Many measurements are used to measure and assess the intensity of training: heart rate, speed, sensation, lactate value, and much more. However, these measurements are often complicated to take (e.g. lactate), or they are dependent on external factors. For example, heart rate reflects the physiological effect of exerting power, and therefore rises and falls comparatively slowly. It is also greatly dependent on other factors such as temperature, training time, prior exertion and diet.

Power meters enable current power to be measured objectively, and quantify the exertion of training and competition.

It is common practice to train across different areas. A power meter enables you to hit these areas precisely. You can make your coach happy, and, more importantly: you can get the best out of your limited training time! This also permits you to track your training progress easily.

What types of power meters are available?

The placement of the sensor is the greatest difference between power meters. The following measuring points are currently common:

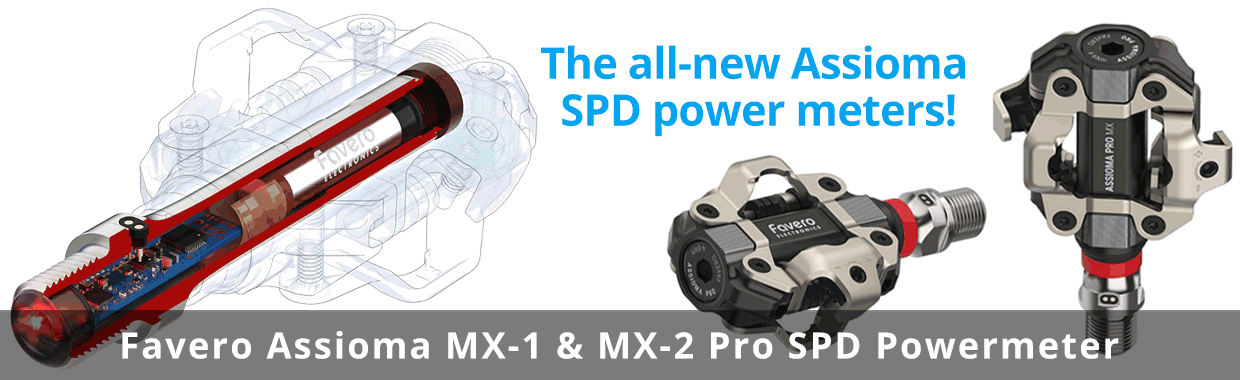

1. Crankset (SRM, Rotor) 2. Pedals (Assioma, Garmin Rally) 3. Crank arm (Stages Powermeter, Rotor Inpower, Inpeak) 4. Trainer (Wahoo Kickr, Wahoo Kickr Core)

Dual-sided or single-sided?

In recent times, new power meters have been marketed which only measure the force exerted by the left leg. For single-sided power meters, the value of the left leg is simply doubled to reflect overall power.

The sensor for single-sided power meters is normally located on the crank arm as with the Stages Powermeter or directly on the pedal (e.g. Assioma Uno power meter or Garmin Rally 100)

Of course, the lower cost of a single-sided power meter is a big plus. For most athletes, a single-sided power meter is sufficient, in our experience.

But what do you do if you have one leg stronger than the other? Unfortunately this applies to most of us. However, the differences are not very large. If there is a pronounced imbalance (e.g. 40:60 or more), a single-sided power meter will no longer be reliable, as it assumes that force is distributed evenly between the right and left.

Some dual-sided power meters can measure the force of both legs independently of each other. Power meters with two completely independent pedal sensors (Assioma, Rally) are particularly worth singling out here. In addition to power and pedal rate, they provide more in-depth information on analysing pedalling technique.

This information can be very useful to help ambitious cyclists improve performance and be more efficient. Training can be tailored to an individual's particular strengths and weaknesses, improving efficiency and pedalling technique.

Which bike computers are compatible with them?

Most power meters transmit via ANT+ and can be used with ANT+ bike computers. Some power meters are also compatible with the newest smartphones, thanks to Bluetooth smart technology.

Powermetershop.de - top-notch service

Our years of dealing with power meters — as sportspeople and trainers — mean that we can give you the best advice on the advantages and disadvantages of the various systems in the power meter market, which is constantly changing. For example, we can give concrete recommendations as to how compatible the various power meter systems are with different bottom bracket bearings, chain rings, etc.

We are happy to help you!

Powermetershop.de - availability and delivery

We have many products in stock. This is because we want you to get your power meter or accessory as quickly as possible. If we don't have a product in stock and this makes the delivery time a bit longer, we'll let you know: the delivery time is listed on the item's page, directly under the price. The inventory is updated in real time so you can be sure that you'll soon be holding your power meter in your hands. It goes without saying, but, unfortunately, there are untrustworthy providers in the power meter market who advertise fraudulent availabilities.

Goods are shipped with DPD, UPS or DHL. You will receive a shipping confirmation and a tracking link when your order is shipped.

You can find more information about shipping costs here.

Powermetershop.de – payment options

You can choose from various payment methods at checkout. We offer PayPal, credit card, prepayment and cash on delivery. There are no surcharges for different payment methods and the entire checkout and payment process is encrypted with 256bit SSL. You can find more information about the payment methods we offer here.

Powermetershop.de - best-price guarantee

We offer a best-price guarantee for many products in our shop. If you can find a product at another German provider for a better price, we won't just give you it for the same price: we'll give you an additional 1% discount.

The best-price guarantee applies to all the products in our shop that are marked with the best-price guarantee symbol. You can find more information about our best-price guarantee here.